| GDSTAS – Triaxial Automated System The Triaxial Automated System (GDSTAS) is a load frame based triaxial testing system. The system is configured by choosing from a range of load frames, triaxial cells, pressure controllers and software. The system can be configured as a multi-station commercial testing apparatus right through to high range rock testing at research level. If an existing triaxial system requires upgrading, parts of the GDSTAS system can be incorporated with existing equipment (including those from other manufacturers) to perform the upgrade. Typical drained and undrained shear strength parameters, such as the angle of internal friction and cohesion, can be obtained from the GDSTAS to enable stability analyses to be carried out for embankment dam design.

|

| GDSTTS - Triaxial Testing System The Triaxial Testing System (GDSTTS) is a fully automated triaxial testing system designed principally for stress path testing. The GDSTTS is based on the classic Bishop and Wesley type stress path triaxial cell, which applies axial and radial stresses directly to the soil specimen. Stress paths that relate to a specific construction and operational sequence for embankment dam materials may be applied to test specimens in this system, allowing the unique soil response to be observed and dam designs to be optimised. |

| GDSVIS – The GDS Virtual Infinite Stiffness Loading system Is the premier load frame in the GDS range with load capacities of 250kN, or400kN. The GDSVIS load frames are designed to be stiffer than classical loading frames. This is to allow more accurate testing of stiffer specimens with less equipment compliance. Furthermore each GDSVIS is internally calibrated to allow automatic self-compensation for any remaining compliance. This type of frame is exclusive to GDS. When combined with a triaxial cell, pressure/volume controllers, and data acquisition, the GDSVIS enables typical drained and undrained shear strength parameters to be determined for use during stability assessments of existing and planned embankment dams. |

| ETAS – The Environmental Triaxial Automated System Is a temperature controlled load frame-based triaxial testing system. Key features include, Frozen Soil Testing, Gas Hydrate Testing, High Pressure Testing and High & Low Temperature Testing. The -20oC cooling system provides ideal conditions for frozen soil testing. Its high pressure testing capability (up to 100MPa) along with low temperature provides the ideal environment for Gas Hydrate Testing. The system also has the option for a Heating only system. Such options enable the ETAS to conduct triaxial tests across a range of temperatures and confining pressures, plus provide typical drained and undrained shear strength parameters for use during stability assessments of existing and planned embankment dams. |

| ETTS – The Environmental Triaxial Testing System Is a temperature controlled testing system for stress path testing. Key features include, Frozen Soil Testing, Gas Hydrate Testing, High Pressure Testing and High & Low Temperature Testing. The -20oC cooling system provides ideal conditions for frozen soil testing. Its high pressure testing capability (up to 100MPa) along with low temperature provides the ideal environment for Gas Hydrate Testing. The system also has the option for a Heating only system. Such options enable the ETAS to conduct triaxial tests across a range of temperatures and confining pressures, plus provide typical drained and undrained shear strength parameters for use during stability assessments of existing and planned embankment dams. |

| ELDYN – The GDS Enterprise Level DynamicTriaxial Testing System Is an entry level dynamic triaxial system, based on an axially-stiff load frame with a beam mounted electro-mechanical actuator. The ELDYN has been designed to fulfill the demand within the geotechnical laboratory testing industry for a lower cost, more basic dynamic triaxial testing system, yet still perform to the very advanced standards that customers expect from GDS. This enables the ELDYN to provide typical drained and undrained shear strength parameters, as well as the cyclic response of soil, for use during stability assessments of existing and planned embankment dams. |

| DYNTTS – The Advanced Dynamic Triaxial Testing System Is a high-end, no compromise testing apparatus combining a triaxial cell with a dynamic actuator capable of applying load, deformation and stresses up to 10Hz. The cell itself is screw-driven from an integral base unit housing the motor drive. Axial force and axial deformation are applied through the base of the cell. The system can be combined with a dynamic cell pressure actuator such that cell pressures may also be applied dynamically up to fundamental frequency of the machine (i.e. 2Hz, 5Hz or 10Hz). These features allow the DYNTTS to provide typical drained and undrained shear strength parameters, as well as the cyclic response of soil, for use during stability assessments of existing and planned embankment dams. |

| GDSTTA – The GDS True Triaxial Apparatus Has the defining characteristic that, unlike conventional triaxial apparatus, all three principal stresses can be controlled independently, rather than just two in a conventional triaxial system. This allows a wider range of complex stress paths to be performed. This dynamic cyclic system is powered by advanced electro-mechanical actuators or optional hydraulic actuators and is an extremely sophisticated research tool. Vertical and one horizontal axis are loaded via the dynamic actuators (axis 1 and 2), stress control is provided for the 2nd horizontal axis, (axis 3) via cell pressure. Altogether the GDSTTA can be used to apply a wide range of stress paths to soil specimens, including those relevant for stability assessments of existing and planned embankment dams. |

| GDSSS – ShearbaseSystem The Shearbase System (GDSSS) is an electro-mechanical shear testing device that can be configured as either a direct shear or direct simple shear test apparatus. The benefit of this apparatus is that the conversion between direct shear and direct simple shear is straightforward, and therefore if both options are not supplied at time of build the missing option can be supplied at a later date. Note slow cyclic loadings may also be applied to test specimens using the SS, allowing multi-reversal tests to be automated and the residual strength of a soil at large strain to be estimated. |

| GDSBPS – BackPressured Shearbox The Back Pressured Shearbox (GDSBPS) is used to perform static direct shear tests on soil specimens with precise back pressure control. Note the static GDSBPS range includes a saturated version providing control of pore water pressure, and an unsaturated version providing control of pore water and pore air pressures. Direct shear tests may be performed using constant volume or constant normal stress conditions.

|

| EMDCSS – ElectromechanicalDynamic Cyclic Simple Shear The Electromechanical Dynamic Cyclic Simple Shear device (EMDCSS) is used for the simple shear testing of cylindrical soil specimens. It is capable of carrying out dynamic cyclic tests from small strain (0.005 % shear strain amplitude) to large strain (10 % shear strain amplitude), as well as extremely accurate quasi-static loading. The easy-to-prepare specimen is subjected to principal stress rotation representative of soil responses directly under an embankment dam. Note user-defined cyclic loading patterns, such as acceleration time histories recorded during earthquake shaking, can also be applied to the test specimen when using the EMDCSS. |

| ST-RTS – Static Triaxial Rock Testing System Is a triaxial system which enables load application up to 12MN using a passive triaxial cell and stiff load frame. Triaxial confining pressures of up to 70MPa are common when using this system. The ability to apply high loads and pressures with the ST-RTS makes the system useful when determining strength and deformation parameters of rock specimens as part of stability assessments for existing and planned embankment dams. |

| DT-RTS – Dynamic Triaxial Rock Testing System Is a cyclic triaxial system designed to apply loads up to 450kN, at loading frequencies of up to 20Hz. Triaxial confining pressures of up to 70MPa may be reached with this system, due to use of a dynamic ratio loader to ensure cell pressures are consistently controlled. The ability to apply high loads and pressures dynamically with the DT-RTS makes the system useful when determining strength and deformation parameters of rock specimens as part of dynamic stability assessments for existing and planned embankment dams. |

| GDSAV – Acoustic Velocity transducers Measure the P- and S- wave velocities within a test specimen. Sensors and sources can be mounted in either the pedestal and top-cap, or both sides of the specimen in some cases, enabling acoustic velocities to be measured in multiple directions. Such small-strain information is often required when conducting stability assessments of existing and planned embankment dams with foundations bearing on rock deposits. |

| DYNBPS– The Dynamic Back Pressured Shearbox

Is used for static and dynamic direct shear testing on soil specimens with control of pore pressures. The control of pore pressure during direct shear testing allows real-world situations to be modelled in the laboratory. This dynamic version of the device allows a landslide to be modelled as it quickly gains velocity after the initial moment of failure. Cyclic direct shear testing is also possible while still controlling and measuring pore pressure. While initially designed for landslide testing, the DYNBPS offers typical shear strength parameters of soil useful for stability assessments of existing and planned embankment dams.

|

| GDSLADS – GDS Large Automated Direct Shear System

Is an electro-mechanical direct shear testing device for large specimens, up to 300mm square or round. Different specimen sets can be used to monitor the response of geo-membranes and rock specimens under direct shear deformation. These options make the GDSLADS a useful tool when determining strength parameters required for stability assessments of existing and planned embankment dams. |

| VDDCSS – The variable direction dynamic cyclic simple shear system

Allows simple shear to be performed in two directions, rather than the standard single direction. This is achieved by having a secondary shear actuator that acts at 90 degrees to the primary actuator. When used as a variable direction machine, the secondary shear axis can be used independently or in conjunction with the other shear axis. Therefore, simple shear may be performed in any horizontal direction. Such features allow strength parameters required for stability assessments of existing and planned embankment dams to be determined. |

| GDSIST – The Interface Shear Tester Is a CRS consolidation cell with the additional ability that the base pedestal may infinitely rotate. The internal load cell measures both the axial force on the specimen as well as the torque generated. The system is designed to test the shear interface between the specimen and the top-cap. Users may bond specific materials to the top-cap for testing. Such features allow the GDSIST to define interface strengths between materials, as well as determine the residual strength of soils as part of embankment dam stability assessments. |

| GDSHCA– The GDS Small-Strain Hollow Cylinder Apparatus

Allows for rotational displacement and torque to be applied to a hollow cylindrical specimen of soil. Using this device it is possible to control the magnitude and direction of the three principal stresses. Studies can for example be made to assess the effect of anisotropy of soil specimens, principal stress rotation, and the effect of varying intermediate principal stress. Two versions of the SS-HCA are available: A dynamic (SSHCA d), and a lower cost static (SS-HCA s) version. Each version can however be used to determine typical drained and undrained shear strength parameters for use during stability assessments of existing and planned embankment dams.

|

| GDSAOS – The GDS Automatic Oedometer System Is the modern replacement for a traditional hanging weight oedometer. The GDSAOS is a self-contained stepper motor driven unit that can be controlled using its Smart Keypad, or from a PC using a USB interface. There is no requirement for compressed air or manually placed weights. When used with the GDSLAB control and data acquisition software, the GDSAOS can be used for a complete array of tests beyond those which a hanging weight oedometer can perform. This includes determination of consolidation parameters useful when assessing the performance of existing and planned embankment dams. |

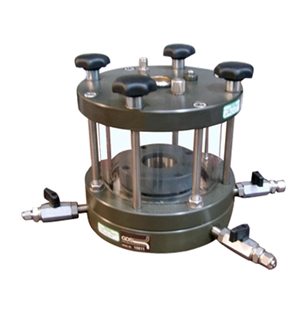

| GDSCTS – The GDS Consolidation Testing System Is a state-of-the-art, fully-automated consolidation testing system designed for soil. The system is based on the Rowe and Barden type consolidation cell using GDS pressure/volume controllers from the Advanced, Standard, or Enterprise range. Two of these pressure controllers link to the computer, one for axial stress and axial displacement control and one for setting back pressure. Such functionality enables the GDSCTS to determine consolidation parameters useful when assessing the performance of existing and planned embankment dams, including permeability (with the addition of one pressure/volume controller). |

| GDSCRS – The GDS Consolidation Constant Rate of Strain cell Is designed primarily for advanced commercial testing laboratories who want to reduce the time required to complete a consolidation test. The CRS cell fits either a new GDS or existing load frame in place of a triaxial cell. The load frame-based one dimensional consolidation cell is capable of applying back pressure and measuring pore pressures up to 1MPa (low pressure version) or 20MPa (high pressure version). Overall the CRS system allows consolidation parameters useful when assessing the performance of existing and planned embankment dams to be determined quickly and accurately. |