GDS have 4 design engineers based at their offices in Hook, who design new and adapt existing products to meet the needs of their customers. GDS actively encourage those customers looking for a bespoke product to be involved in the design process and often have customers visiting the design office to review drawings. The production and quality assurance of each product is done onsite at GDS' offices in Hook. This helps produce a consistently high level of apparatus and allows the customers the opportunity to see the product working before it is shipped.

Examples of bespoke testing equipment.

Below are a few examples of the bespoke equipment GDS has designed for customers.

- Adapted a typical Electromechanical Dynamic Triaxial Testing System (DYNTTS) to hold a 300mm sample. Typical sample sizes were up to 150mm.

- GDS CO2 consolidation cell. A University approached GDS about a particular test they wanted to run. Their ideas and designs were reviewed, a few suggestions were made and a detailed design was produced. Once the University were happy GDS manufactured and installed the cell. Click here for more information on the C02 cell.

- A smaller project GDS recently worked on was a soft soil membrane jig for a customer,

- ENSG & GDS developed a device to monitor the radial profile of the specimen whilst under test using highly accurate laser precision. Click here to read the case study.

- Together Politecnico di Torino and GDS Instruments, teamed up to design and develop a new direct shear box to help investigate the effects of the Beauregard Dam in the Aosta Valley in Italy, click here to read the case study.

Testimonial

“The shear testing apparatus designed by GDS Instruments and PoliTo has many innovative features for a direct shear device. Its advanced characteristics, in particular its capability to apply high back pressures to the sample and apply 100kN both axially and in the shear direction, allow for testing to be conducted in a variety of ways. In particular, the shear behaviour of an intact specimen can be investigated under a change of pore pressure as observed in field conditions. It is shown that the new equipment is working properly and that the accuracy of the measurement system implemented allows one to obtain relevant results during both the shearing and creep stages”, says Barla.

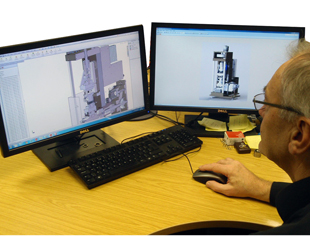

GDS Design Team

| | GDS have a team of in-house engineers who design all of their products at the office in Hook. If you are starting a new project, would like advice on how to change an existing product or would like a product similar to one of GDS' products with a few tweeks, contact us today, info@gdsinstruments.com.

|